compression test conclusion|Compression Testing: Exploring Methods, Applications, and Benef : manufacturing Compression testing involves subjecting a material to compressive forces until it deforms or fails. A sample is placed between an upper and lower fixture, such as parallel compression plates or specific application-driven fixtures. 1 de fev. de 2023 · Um urso foi flagrado tirando centenas de "selfies" em meio a árvores em Boulder, no Colorado, Estados Unidos, disseram as autoridades responsáveis pelo Espaço Aberto e Parques de Montanha .

{plog:ftitle_list}

Você pode fazer a sua aposta na Lotofácil até uma hora antes do sorteio nas lotéricas credenciadas e no site oficialda Caixa. Ou seja, é possível registrar o . Ver mais

Conclusion. Compression testing is a vital technique in materials science and engineering, providing essential data on the mechanical properties of materials under . Compression testing is used to determine how a product or material reacts when it is compressed, squashed, crushed or flattened by measuring fundamental parameters that determine the specimen behavior . Compression testing involves subjecting a material to compressive forces until it deforms or fails. A sample is placed between an upper and lower fixture, such as parallel compression plates or specific application-driven fixtures. Compression testing is used to determine how a material will behave under an applied load, usually by applying compressive pressure to a test specimen (usually a cylindrical geometry or a cuboid) using a platen on a .

Key Takeaways from Compressive Testing. Compressive testing is a mechanical test used to measure the compressive strength of materials. It requires equipment and .In compression testing, the sample or the component is compressed between two moving platens. A load cell and an extensometer or strain gauge are used to measure load and displacement. .

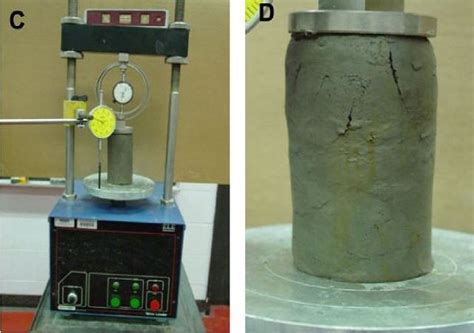

There have been very few systematic studies of size effects in compression, and the problems with testing make it difficult to draw firm conclusions. Nevertheless there are strong .11 Unconfined Compressive Strength Test. Introduction. The unconfined compression test is the most popular method of soil shear testing because it is one of the fastest and least expensive methods of measuring shear strength. It .

The goal of compression tests is to detect the behavior or response of materials and obtain the corresponding compressive properties (such as ultimate compressive strength σUCS, yield . An unconfined compression test is a simple and effective method to test the maximum load a testing a concrete sample can withstand under axial strain. The test involves applying an axial load along the sample’s longitudinal .A compression test is conducted in a manner similar to a tensile test except that the force is compressive and the specimen contracts along the direction of stress. Equations (1) and (2) . and the problems with testing make it difficult to draw firm conclusions. Nevertheless there are strong indications that the fibre direction compressive .

By performing a compression test, internal engine malfunctions; such as bad valves, piston rings or excessive carbon buildup can be detected, before they cause irreparable damage. . Conclusion. So, testing compression, is really nothing more than a way to figure out, which cylinder has a problem. And, if you do find any issues, the next step .Apparatus for Concrete Cube Test. Compression testing machine. Preparation of Concrete Cube Specimen. The proportion and material for making these test specimens are from the same concrete used in the field. Specimen. 6 cubes of 15 cm size Mix. M15 or above. Mixing of Concrete for Cube Test. Mix the concrete either by hand or in a laboratory . Test methods. The compression tests of the specimens with the loaded cross-section of 30 × 30 mm 2 were carried out on an Instron testing machine with an in-line 100-kN load cell under displacement controlled loading at a rate of 0.3 mm/min. The compression tests of the specimens with the loaded cross-section of 60 × 60 mm 2 and 90 × 90 mm 2 were .

A compression test is simple to learn and only requires a few basic tools. From a mechanical perspective, you will need to know how to properly remove the spark plugs on the vehicle or equipment you are testing and properly disable the ignition system and fuel system, the latter if the vehicle is fuel injected. For carbureted engines, you can choose to disable the fuel supply . In conclusion, troubleshooting compression testing for a diesel engine requires addressing inconsistent compression readings, difficulties in removing glow plugs, and test equipment malfunctioning. By following the tips and steps provided in this section, you can effectively identify and resolve these issues, ensuring accurate testing results.

High shear stresses in this area may also interact with compressive stresses, and this type of test tends to underestimate the intrinsic compressive strength [56]. There have been very few systematic studies of size effects in compression, and the problems with testing make it difficult to draw firm conclusions.

Test the specimens by compression test machines after seven or 28 days of curing. Apply the load gradually at a rate of 140 kg/cm2 per minute until the specimen fails. . In conclusion, testing is an invaluable tool in materials science and various industries, such as construction, automotive, and aerospace. By understanding the concepts . Conclusion; A compression test will tell a lot about your car’s engine and its health. But before getting your hands dirty you need to learn how this procedure is done. You need to learn what is a good compression test reading and what is a bad compression test reading. Whether you should compression test a cold engine or compression test a . Finally, when good compression exists, you can expect a cylinder, to gradually and evenly raise pressure. TIP: You can also do a, A running (dynamic) compression test. So, if you do find any issues, the next step would be doing a cylinder leak down test. A cylinder leak down test, is similar to a compression test. Because, it tells you how well .

What is Compression Testing? The Theory and

The raw data of a triaxial test include the dimensions of the sample, the lateral pressure σ3, the axial load P, the duration of the test, which must be within the required limits, and, if strain gauges are utilized, the deformation measurements.

The main conclusion of various theoretical models and experiments is that, as the specimen size increases, its compressive strength decreases. . During a standard compression test, say, according to ASTM C39 [120], frictional forces are generated between the contact surfaces of the concrete and the loading plates. This results in a non-axial .Compression Test Lab Report. Prepared by UMP students faculty of mechanical engineering the name of allah, the most beneficent, the most lab compression test (Skip to document. University; . Conclusion / 10. Writing Skill / 5. Total / 100. Lab Objectives. By the end of this lab, students should be able to: Conduct compression test for . where P a = atmospheric pressure (≈100 kN/m2; ≈2000 lb/in2). \( N_{60}^{0.72} \) is the blow count of SPT and Cu is the undrained shear strength of clay. In this paper, we leverage this equation, shown in the methodology section and use it to predict unconfined compression strength (q u) from various parameters like soil type, N-value and depth.

Compression Test Lab Report - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. 1. The objectives of the compression test were to study the application of strain gauges to obtain .

2. To identify and determine the mechanical properties of given metal alloy by carrying out uni-axial tension-compression test. Introduction: A compression test is any test in which material experiences the opposing forces inward upon the specimen from opposing side or otherwise compressed, crushed, and flattened. Test Procedure. Measure the dimensions of the wooden sample using a vernier caliper. Place the wooden sample in the universal testing machine such that the grain fibers are parallel to the applied compressive load. Attach the deflection dial gauges to the sample. Start loading the sample in compression.Unconfirmed Compressive Strength (UCS) stands for the maximum axial compressive stress that a specimen can bear under zero confining stress. Due to the fact that stress is applied along the longitudinal axis, the Unconfined Compression Test is also known as Uniaxial Compression Test. UCS is a parameter widely used in geotechnical design, but . In conclusion, the compression test is a vital tool in engineering, providing key insights into the compressive strength of soils and rocks. By understanding the importance of this test, the equipment involved, and the process of soil sample tube preparation, engineers can obtain accurate and reliable data on the soil’s stability and capacity

Engine CompressionAtmospheric pressure at sea level is approximately 14.7 psi.A 9:1 compression ratio cylinder is compressing the air and fuel mixture to about 132 psi at sea level (9x14.7=132.3 .Compressive Strength Test of Concrete. The compressive strength test of concrete is an essential procedure that helps engineers and construction professionals evaluate the strength and durability of concrete structures. The test is commonly done on concrete cubes, using a compressive testing machine to determine the maximum compression load the cube can .

Understanding compression test results is crucial for assessing the health of an engine. High compression ratios may indicate efficient combustion and a properly-functioning engine. . Conclusion. To sum up, calculating compression ratio through a compression test is a crucial step in maintaining the health and performance of your engine. By .

During this experiment, a compression test is done on cast iron, lead and wood. The compression test for the cast iron is used to draw the engineering stress- strain graph for the cast iron which from we were able to calculate the mechanical properties for the cast iron and compare it with the results in case of tension.9.13 Compression test. Compression testing is one of the most important tests to determine the behavior of composite materials. Mechanical properties of composite materials can be altered by giving a load to the composite materials, but the properties are difficult to measure directly by a compression test machine. . In conclusion, the yield .

Understanding Compression Testing and Flexural

Worn valves, valve seats and valve train normally cause uneven compression. If only one cylinder has low compression, a burned exhaust valve, broken valve spring or broken piston rings are indicated. Dry/Wet Compression Testing – The classic wet/dry compression test is intended to detect worn piston rings by comparing cranking compression .

Unconfined Compression Test. The unconfined compression test is by far the most common, cheap and fastest method for soil shear testing. The unconfined test is used for cohesive, saturated soils. This test is inappropriate for dry sand or crumbly clays. This is essentially a special case of the triaxial compression test where the minor .

webTodos os resultados de Jong PSV na temporada na ESPN (BR). Inclui todos os resultados de Jong PSV nas competições nacionais e internacionais.

compression test conclusion|Compression Testing: Exploring Methods, Applications, and Benef